Maximum design freedom

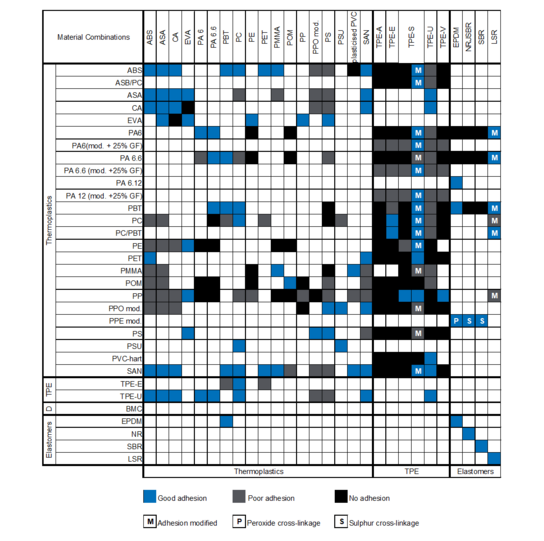

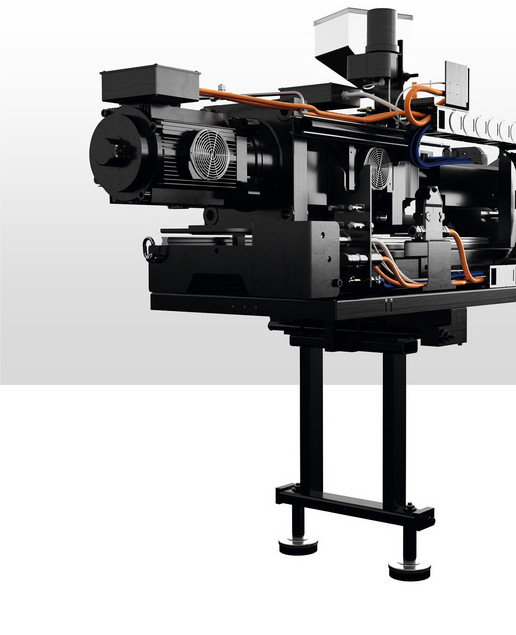

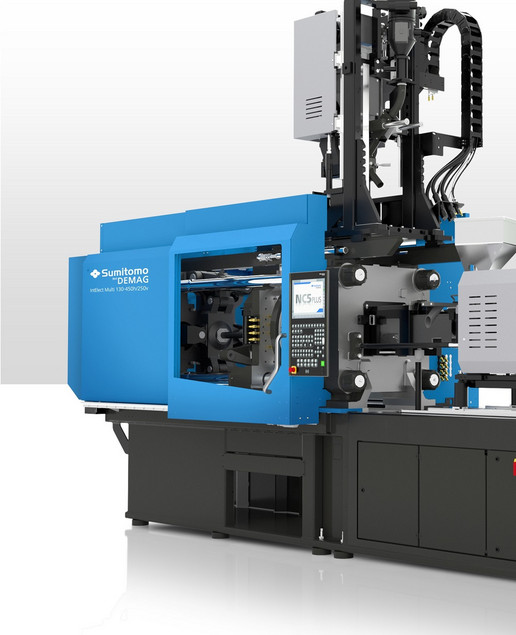

High-quality multi-colour design, lower-cost parts, complex moulded parts comprising two or more components. All of these factors have contributed to the rapid adoption of multi-component moulding. It involves injecting two or more different materials into the same mould in a sequential or simultaneous manner to create a single product. This process is widely used in the automotive, electronics, consumables and medical industries, where functionality, highest quality, or aesthetically-pleasing products are in high demand.

- Turntable process – production of multiple component parts through turning of the ejector side

- Index platen – production of multiple component parts through transferring the article from one cavity to further cavities

- Bi-injection moulding – simultaneous or delayed injection of two components into the same cavity

- Core-back process – injection of two components into one cavity in sequence; cavity for second component is released by pulling a gate-valve

- Transfer process – preform is transferred manually or by robot to the second cavity or second machine

- Reduced assembly effort

- Increased quality assurance and reproducibility

- Less floor space and less machine setup time required

- Reduced energy consumption

- No compromises in application design (haptics, colours, materials)

- Consumer goods/Automotive industry - Products with multiple colours, materials or haptics features

- Automotive/Medical/Electronics industry - Functional parts with special features