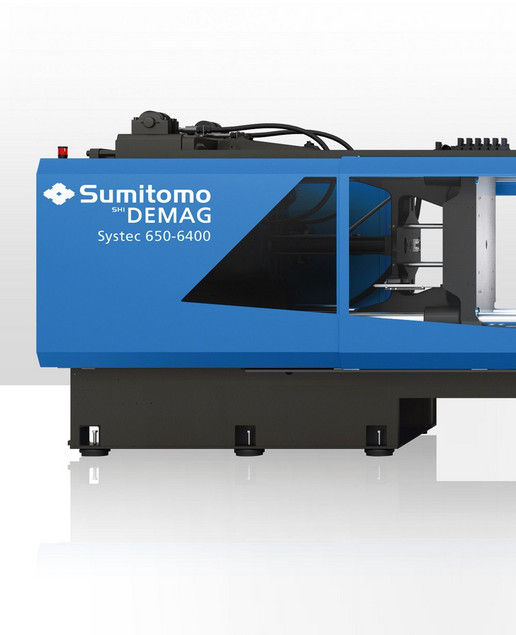

Plastics for high performance applications

Thermoset injection moulding is a specialised manufacturing process used to produce plastic parts with exceptional strength, durability, and heat resistance. Unlike thermoplastic materials, thermoset plastics undergo a chemical reaction during the moulding process, resulting in a permanently cross-linked structure. This unique property makes thermoset plastics ideal for applications in the automotive, aerospace, and electrical industries, where high strength and resistance to heat, dielectric strength and chemicals are critical.

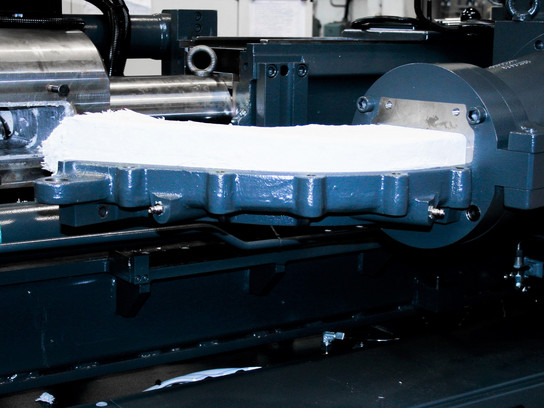

- Bulk moulding compound (BMC)

- Free-flowing thermosets

- High dielectric strength

- Good price-performance ratio compared to metals or high-performance plastics

- Exceptional mechanical properties

- Resistance to high temperatures

- Excellent chemical resistance

- Well suited for producing large and complex parts with tight tolerances

- Automotive industry (turbocharger housings, electric motors for electric mobility)

- Electronics industry (heat-resistant and dielectric strength resistant)