Electrification everywhere

From automotive to consumer electronics and construction, demand for electronic components is at an all-time high. With touch surfaces, intelligent displays, and hybrid components becoming the norm, manufacturers must be able think in terms of holistic, automated and networked processes. Our innovative high-speed and high-precision systems are designed to meet these challenging, offering modular, flexible and dynamic solutions.

Electronics expertise at Sumitomo (SHI) Demag

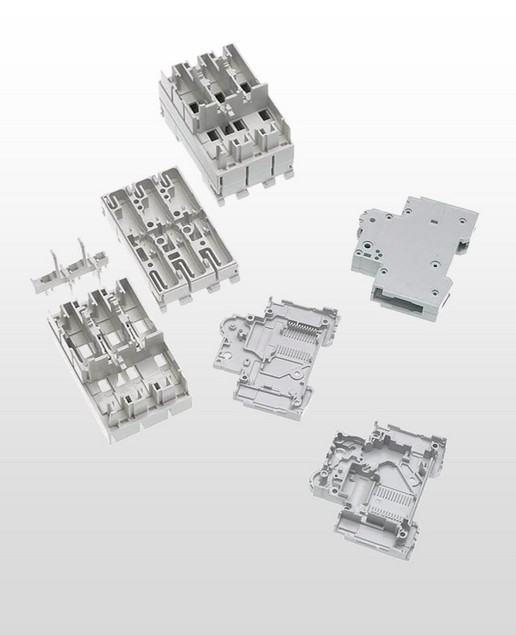

Experts in electronic components

We have decades of experience partnering with companies in the electronics industry, producing plug connectors, sensor electronics, and more.

Solutions for every application

Our flexible and modular production systems meet the diverse electronic component requirements used by a wide range of industries.

All-electric machine expertise

Our expertise in all-electric machines guarantees flawless and repeatable part production, with the highest precision.