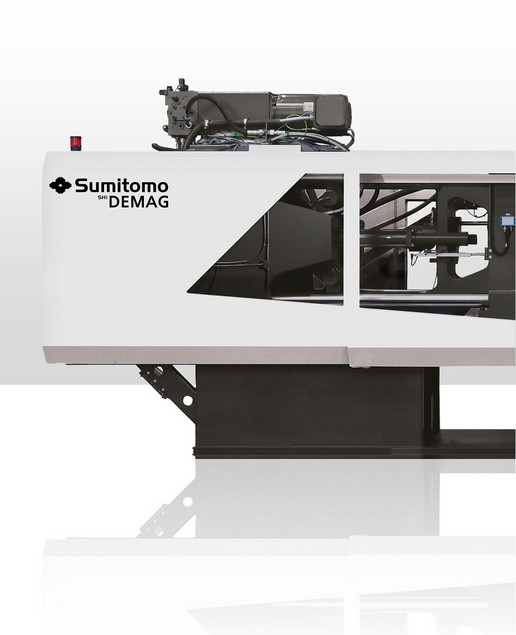

Specially adapted solutions for the medical market

Our systems, equipped with cleanroom certification, high repeatability, compliance documentation, and machine control safeguards, are meticulously designed to meet the stringent requirements of medical application production. Our combination of highly precise machines and specialist global GMP-certified Medical Team, guarantees flawless production for all life-science and pharmaceutical applications.

Medical expertise at Sumitomo (SHI) Demag

Mould-maker network

Save time and costs, by testing your moulds on our machines that are available at our extensive mould maker network.

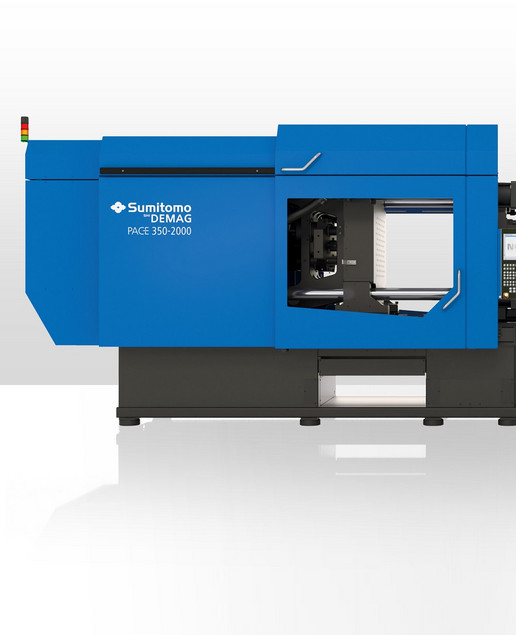

Medical package

Our all-electric IntElect features a standardized cleanroom package to reduce particle contamination in the mould area.

GMP-certified team

Our globally-active Medical Team have all the expertise needed to support medical customers with every aspect of production, compliance and documentation.