Connectivity and low emissions

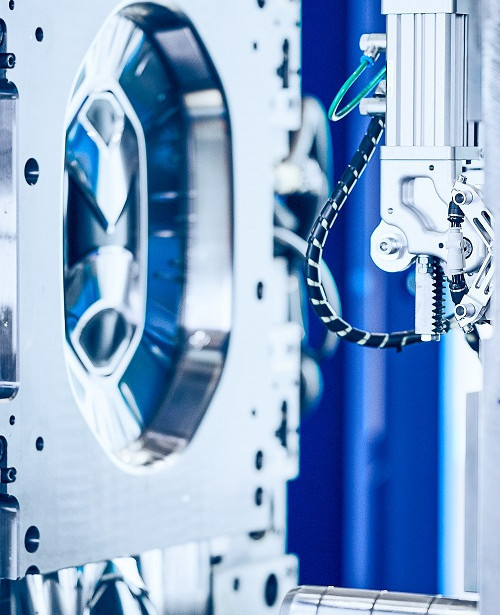

Plastic is a vital resource in enabling the future of mobility, from lightweight designs and autonomous driving to digital networking and driver information systems. Our expert teams specialise in providing solutions to produce high-quality plastic parts for various automotive applications, including functional interior and exterior parts, electronic components, lighting, and more.

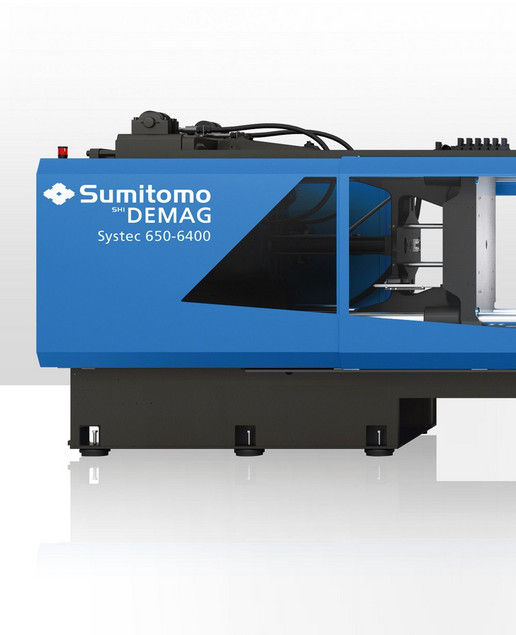

Automotive expertise at Sumitomo (SHI) Demag

Process expertise

Our highly specialised and experienced teams cover all the relevant processes for the automotive industry, providing comprehensive solutions to meet your needs.

Highest flexibility

Our modular and versatile solutions are designed to adapt to the dynamic demands of the industry.

Project planning

The combination of our project planning expertise and turnkey systems helps to deliver reliable production setups for your company.