Vienna/Tulln – The Rejlek Group in Vienna has recently commissioned Austria’s first fully integrated SAM-C automation solution from Sumitomo (SHI) Demag. The fully electric IntElect 130 impresses the Austrian manufacturer of high-precision plastic components with outstanding process stability, energy efficiency, and precision. Marking an important step toward sustainable manufacturing.

“For us, the combination of cost-performance ratio and technical sophistication was decisive,” explains Johannes Burtscher, Operations Manager for Injection Molding and Stamping Technology at Rejlek “The machine offers an exceptional value creation depth – from the drive technology to the integrated robotic solution. What particularly impressed us was the seamless integration of the SAM-C robot, which significantly simplifies operation and maintenance.”

Higher productivity with low energy consumption

Rejlek manufactures precision components in Vienna for industrial electronics, mobility, and medical technology. On the new fully electric IntElect, plastics with high glass fiber and recycled content are processed – a significant step toward more sustainable production. “Our machine is designed to safely process even recycled materials,” says Burtscher. “This allows us to directly reuse production waste and efficiently close the material loop.”

Thanks to the activeMeltControl technology, the machine automatically compensates for material fluctuations, ensuring consistently high quality with minimal scrap rates. The adaptive control system adjusts the injection process in real time, enabling particularly stable production conditions. A clear advantage, especially when using multi-cavity molds.

Space-saving Automation with System Integration

A key feature of the new production cell is the fully integrated SAM-C robotic solution. “The compact design saves valuable floor space, and thanks to the joint control of the machine and robot, operation is extremely intuitive,” explains Burtscher. “This reduces training requirements and downtime.”

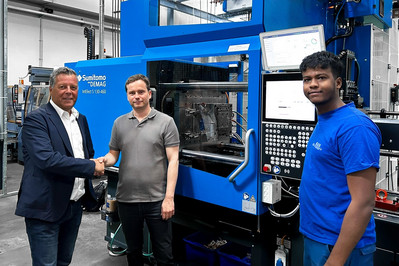

In the production process, the SAM-C robot performs precise part removal and handling for subsequent processing steps, making a decisive contribution to higher process reliability and consistent product quality. Michael Domes, Managing Director Sales Austria at Sumitomo (SHI) Demag, adds: “With the SAM-C series, we offer a fully integrated automation solution that is perfectly tailored to our fully electric machines. The combination of high dynamics, energy efficiency, and ease of use provides our customers with new opportunities to manufacture more productively and sustainably.”

Sustainability as a Core Practice

At Rejlek, sustainability has long been an integral part of daily production. In addition to using recycled materials, the company optimizes cooling management and relies on closed water circuits. “Our fully electric system significantly reduces energy consumption compared to hydraulic machines,” emphasizes Burtscher. “At the same time, we benefit from precise, stable cycles and very high Overall Equipment Effectiveness (OEE).” The technology thus supports both the company’s ecological and economic objectives – an aspect that is equally central for Rejlek and Sumitomo (SHI) Demag.

Partnership on Equal Terms

The collaboration between Rejlek and Sumitomo (SHI) Demag has developed over many years. About every tenth injection molding machine at the Vienna site comes from the German-Japanese manufacturer. “The relationship is characterized by trust, technical depth, and short communication paths,” says Burtscher. “We see great potential to further expand the partnership in the area of multi-component technology in the future.”

For Michael Domes, the installation of Austria’s first SAM-C cell marks another milestone: “Rejlek impressively demonstrates how precision, automation, and sustainability can be harmonized. The implementation confirms that fully electric production is convincing not only technologically but also economically.”