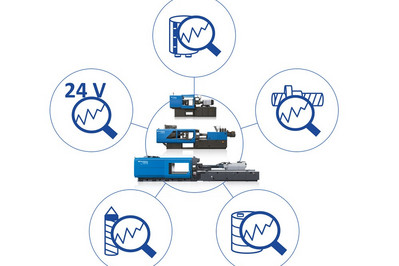

“At Fakuma 2021, the company will present three real-time diagnostic options that can be implemented across our entire machine series," reports Dr. Thorsten Thümen, Senior Director Technology, Sumitomo (SHI) Demag. “The first option helps to permanently maintain energy efficiency and power on our all-electric machines. The hydraulic option serves to decode oil parameters and maintain component quality. The third reliably monitors control voltage across the entire injection moulding machine series," he explains.

Initially, the rationale for developing these condition monitoring systems focused on components where failures incur the highest costs and lengthiest machine downtimes. However, further developments to the portfolio of solutions are already underway. “Currently, our efforts are focused on detecting abrasion and wear to the screw, the plasticising cylinder and the ball screws on all-electric injection moulding machines. Our ultimate goal is full monitoring of all critical components prone to wear," says Dr Thümen.

To keep monitoring costs proportionally aligned to the tangible benefits, innovative and equally uncomplicated solutions were intentionally engineered to facilitate faster and easier documentation of machine conditions by plant operators. Fakuma visitors can experience the simplicity for themselves at the company’s exhibition stand 1105 in hall B1.

All-electric machines permanently energy-efficient and powerful

For the DC voltage intermediate circuit supplying the individual drive axles and for the absorption of generator power in Sumitomo (SHI) Demag all-electric IntElect machines, the company has developed a process that detects capacitance changes in the converter supply. This could be a result of aging of the electrolytic capacitors or electrical defects, for instance.

In the event of a loss of capacity, the energy fed back into the cycle can no longer be stored and is dissipated via brake resistors. Depending on progress, machine energy consumption may initially increase. At a certain point, the brake resistor is overloaded, so that the machine can no longer be used for the set cycle.

"This results in unplanned downtime or losses in cycle time with corresponding process deviations," cautions Dr Thümen. The status monitoring of the intermediate circuit capacity developed by Sumitomo (SHI) Demag continuously records the storage capacity of the capacitors reporting a machine-relevant change in time. Any necessary maintenance measures can therefore be planned in advance. "This ensures part production and service can be deployed at the most opportune time."

Hydraulic machines - decoding oil characteristic parameters

In hydraulic machines, oil usage is both the basis for trouble-free operation, yet can also be an indicator of imminent damage. Sumitomo (SHI) Demag offers additional measurement sensors for monitoring two relevant oil parameter groups during machine operation.

Jan Taufer, Project Manager for Condition Monitoring and employee at the Sumitomo (SHI) Demag test centre explains: “On the one hand, a particle monitor continuously records the number and size of particles contained in the fluid. This evaluation follows the quality standard ISO 4406 format, which is displayed as an actual value or trend via the machine."

If a violation of the parameterised warning or alarm limit occurs, a corresponding error message is generated. This enables the machine to be stopped so operatives can search for causes before particles cause damage to hydraulic components (chain reaction of wear) and prompt them to complete a full system flush, the expert explains. Taufer adds: “An unplanned machine downtime lasting several days can therefore be avoided and reduced to a targeted service call.”

A second measuring device detects the physical properties of the oil, such as the water content, permittivity and conductivity. “Based on these measured values, the lubricant age can be determined via internal algorithms, and can be addressed before the chemical properties change to the extent that trouble-free operation can no longer be guaranteed," explains Taufer. “This way, accelerated oxidation or wear processes, cooler breaks or water ingress due to condensation can also be detected and remedied at an earlier stage with minimal effort.”

In contrast to conventional oil analysis, which would only be carried out at regular intervals with the utmost care during sampling, if the stationary hydraulic oil analysis provides a continuous reading of all relevant parameters without the risk of sample contamination, the project manager is kept aware. As a result, the customer benefits from lower labour costs, complete and fully traceable condition monitoring documentation and higher maintenance quality.

Reliable power supply and fast troubleshooting across the series

In the third option, Sumitomo (SHI) Demag offers a system for monitoring the 24 V control voltage of the injection moulding machines across the entire series. Realised by a power supply unit and intelligent circuit breakers that communicate permanently with the machine control, through this application, the actual and effective cycle current can be monitored in real time. "Consequently, potentially critical peaks or generally high utilisation rates can be identified and countermeasures can be initiated at the earliest stage," Taufer explains.

If an error occurs, for example due to a sudden short circuit, this is detected by the controller and generates an alarm. It speeds up troubleshooting considerably, as the causality faulty circuit is identified without any detours. After an error, the availability can be restored much faster, simultaneously generating information about the error cause. "Conventional systems in the event of a fault might protect the system from overcurrent or short-circuit. However, the supply would be interrupted and the machine could suddenly fail,” ends Taufer.